Curious about the effectiveness of soundproof drywall, the top products for soundproofing, and installation techniques? You’re in the right place to find out.

In a nutshell, soundproof drywall does work, effectively blocking sound waves from passing into adjacent rooms.

Furthermore, there are various supplementary products like green glue and resilient channel that can enhance the STC rating performance of soundproof drywall.

Soundproof Drywall – What is STC?

The first step in choosing soundproof drywall is understanding the required STC rating. What does STC stand for? Simply put, it’s the Sound Transmission Class, which rates how well wall partitions handle airborne sound.

Architects specify the STC rating as a guide for determining the sound-blocking capability required for the wall system. It’s the contractor’s responsibility to construct walls that meet these STC requirements.

Typical STC Requirements

- School Classrooms – STC 42 to 52

- Doctor’s Office – STC 52 or higher

- Hotel – STC 48 to 52

- Multi Family Housing – STC 48 to 55

- Exterior Walls – STC 42 – 60

Soundproof Drywall Resources

Your preferred suppliers should be able to provide a concise overview of soundproof drywall. In just a few minutes, they should be able to summarize its key features.

There are only a handful of popular products and manufacturers to choose from. They should be well-versed in the advantages of each product in relation to your project’s specific requirements.

If you’re researching independently, here’s a quick review of soundproof drywall panels, STC ratings, and the best options for noise reduction.

Choosing the Right Soundproof Drywall

When selecting soundproof drywall for your project, several factors come into play.

First and foremost, it’s essential to closely follow the plans and specifications to understand the architect, designer, and owner’s intent. Distinguish the differences between each soundproof product.

Second, thoroughly evaluate the specified products as outlined in the project documents.

Third, consider providing a few alternatives and be prepared to explain the pros and cons of each. Consult with your supplier for recommendations, current pricing, and any procurement challenges or lead times.

What Is Soundproof Drywall Made With?

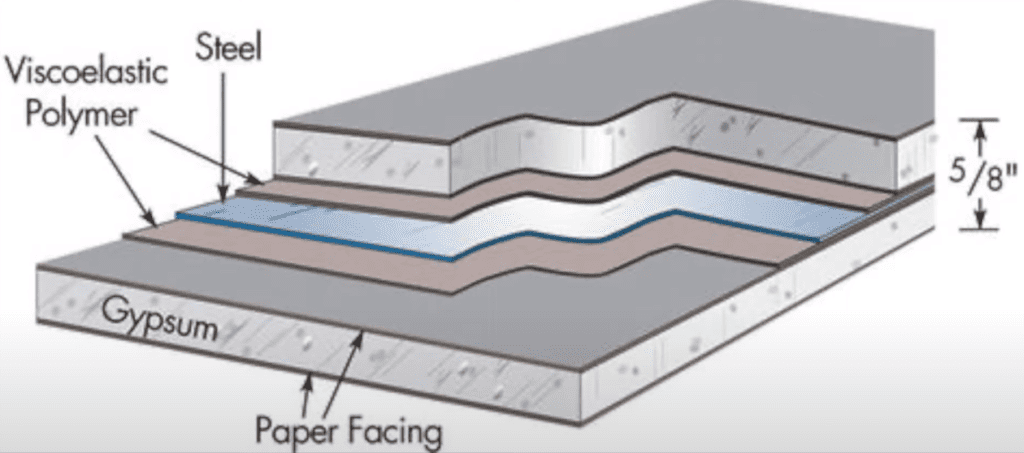

Conventional drywall sheets consist of a gypsum or calcium sulfate core.

Soundproof drywall goes a step further by incorporating ceramics and viscoelastic materials, reducing sound wave transmission.

QuietRock – Soundproof Drywall

QuietRock sheetrock is a popular choice for commercial soundproof drywall applications.

While several options are available, the QuietRock ES, part of the E-Z Snap line, stands out by combining solid Sound Transmission Class ratings with the convenience of installation through scoring and snapping, just like standard drywall.

This approach reduces labor costs when carpenters are installing the sheets. It’s STC rated and tested to minimize noise transmission through walls and floors.

Pabco Building Products has been manufacturing QuietRock since its acquisition from Serious Energy in 2013.

One notable feature of QuietRock panels is their ability to achieve STC ratings without occupying excessive floor space.

Pabco employs “thin wall technologies,” which require less material, minimize wasted space, and reduce installation time.

A single layer of QuietRock can outperform multiple layers of regular drywall, resulting in labor savings.

Given the rising costs of labor and materials, adding a second layer of drywall solely for STC purposes is often an impractical decision.

Additionally, don’t overlook the QuietRock EZ-Snap Mold Resistant panels, which contribute to a healthier indoor environment. These panels’ mold-resistant treatment meets ASTM D3273 standards and is listed in over 90 ULs for fire-resistant assemblies.

SoundBreak Drywall

SoundBreak XP by National Gypsum features a unique purple paper covering moisture, mildew, and mold-resistant, high-density gypsum board.

These components are laminated together with sound-damping, viscoelastic polymer, enhancing the acoustical properties of the gypsum panel’s core. Both sides are protected by heavy paper.

Soundproof Drywall by National Gypsum

SoundBreak can also be cut by scoring and snapping, much like QuietRock. SoundBreak XP 5/8″ thick drywall is Type X fire-rated and can achieve STC values as high as 56 for a single-layer steel stud assembly.

Consider using the SoundBreak XP demo tool for comparing noise levels transmitted between rooms with SoundBreak XP installed on the walls.

SoundBreak XP RetroFit

SoundBreak XP also offers a retrofit product for existing walls. It can be easily scored and snapped and doesn’t require costly acoustical sealant.

The 5/16″ thick gypsum board is attached directly to the existing drywall to increase STC values and address noise issues without extensive demolition or dusty drywall work.

CertainTeed SilentFX QuickCut Drywall

Another option for soundproof drywall is SilentFX QuickCut by CertainTeed. With viscoelastic polymer sandwiched between two dense gypsum cores, SilentFX drywall achieves higher STC ratings than standard wallboard.

CertainTeed’s specially designed soundproof board is easy to score and snap, reducing installation time and labor costs.

SilentFX drywall also features 100% recycled mold and moisture-resistant paper on both sides. It is available in 1/2″ and 5/8″ thicknesses, with the 5/8″ product being Type X fire-rated for partition applications.

STC Ratings for Drywall

Several soundproofing products offer higher STC ratings than standard drywall. Some are UL tested and ASTM rated, while others may not be. Some may provide better results within your budget, while others could be cost-prohibitive.

There are various ways to achieve a higher sound transmission class. Spacing metal or steel studs further apart, from 16″ on center to 24″ on center where possible, reduces sound vibrations by decreasing the material through which sound travels.

Increasing the stud depth from 3 5/8″ to 6″ and adding extra fiberglass insulation can boost the STC rating by 3 to 4 points in your wall assembly.

Furthermore, the use of hat channel or resilient channel and materials like cellulose insulation, rockwool insulation, and porous or perforated wall and ceiling panels can all contribute to enhanced STC ratings.

Understanding the fundamentals of soundproof drywall equips you to meet your customer’s unique project requirements. Stay updated with your trusted suppliers to explore the latest and most effective solutions for your clients.

How Much Does it Cost to Soundproof a Room?

For just a few dollars per square foot, you can soundproof a room to block sound waves and achieve a higher STC rating, preventing sound transmission from neighboring rooms or exterior walls.

While QuietRock is approximately four to five times more expensive than standard drywall, it may reduce the number of drywall layers required, leading to labor savings.

Other Soundproofing Ideas

Many products and building materials claim to reduce sound transmission and airborne noise through walls and ceilings. While soundproof drywall is a practical choice, other products like mass-loaded vinyl or wall-mounted acoustic panels might be necessary to act as sound barriers, preventing unwanted noise from penetrating existing walls.

tag: # Soundproof Drywall